Condition-based maintenance

(CBM or CBM+) is a strategy of performing maintenance on a machine or

system only when there is objective evidence of need or impending

failure. CBM is enabled by the evolution of key technologies, including

improvements in - sensors, microprocessors, digital signal processing,

simulation modeling, multisensor data fusion, reliability engineering, Internet of Things (IoT) connectivity, data warehousing, cloud computing, machine learning (ML), artificial intelligence (AI), and predictive analytics.

CBM involves monitoring the health or performance of a component or

system and performing maintenance based on that inferred health and in

some cases, predicted remaining useful life (RUL).

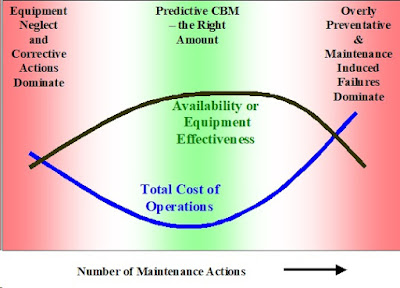

This predictive maintenance philosophy contrasts with earlier

ideologies, such as corrective maintenance — in which action is taken

after a component or system fails — and preventive maintenance — which

is based on event or time milestones. Each involves a cost tradeoff.

Corrective maintenance incurs low maintenance cost (minimal preventative

actions), but high performance costs caused by operational failures.

Conversely, preventative maintenance produces low operational costs, but

greater maintenance department costs. The result is the additional

hidden cost associated with disposing of components that still retain

significant remaining useful life. Such early retirements also drive

more demand for spares and higher procurement costs over the life cycle.

Operational

availability (military) or overall equipment effectiveness (industrial)

is also affected by maintenance choices. Overly corrective or overly

preventive maintenance strategies can reduce true availability through

too much downtime due to maintenance. On the corrective side, running to

failure or near failure typically leads to more significant operational

issues and consequential damage. Lost production, downtime, and more

significant maintenance often result. On the preventive side, the

equipment is often unavailable because it is being more frequently

maintained than optimally required in order to conservatively prevent

failures. There is also a greater likelihood of maintenance-induced

failures, which can have a negative effect on cost and availability. The

more one disassembles or modifies well functioning equipment, the

greater the chance that one will introduce a new problem or confounding

issue.

Implementing better maintenance

practices is driven by the desire to reduce the risk of catastrophic

failures, minimize maintenance costs, maximize system availability, and

increase platform reliability. These goals are desirable for aircraft,

ships, ground vehicles, and industrial manufacturing of all types. Given

that maintenance is a key cost driver in military and commercial

applications, it is an important area in which to focus research and

development efforts and drive continued engineering improvements.

About the Author

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.